Welcome

Welcome to the Ramset Powder Actuated Tool online training. This innovative approach to education combines interactive web-based training techniques and online testing with immediate feedback to provide you a rich learning environment

The course consists of approximately 30 pages of usage, safety and troubleshooting material. At the end of the course students are also given the ability to download individual Tool Manuals.

Upon completion of this brief course you will have the opportunity to take an online exam. Instructions for taking these exams are provided at the end of the course.

Learning Bytes - click these buttons to launch a separate pop-up window which will provide additional information about the topic on that page.

Show Me - click these buttons to play animations which display content graphically. See the Learning Byte on this page for more information about animations.

To move throughout the course, use the following navigation options:

You have completed the orientation information and are now ready to being the course. Good Luck!

If you experience any problems when taking this course, please reach out to Ramset technical support at:

Phone: (877) 489-2726

Email: CS@itwbrands.com

Safety practices are very important when using the Ramset Powder Actuated tools.

Always wear approved eye and hearing protection.

- Failure to wear eye protection such as safety glasses may result in serious eye injury from flying debris.

- Constant or repeated unprotected exposure to fastening noise may cause permanent hearing loss.

Always read tool manuals before operating any tool. Tool manuals are an excellent reference for tool use, safety and maintenance. They contain the information you need to operate the tool safely and effectively.

Operator's Manuals will be available for download in Adobe PDF format upon completion of this course.

With all safety precautions reviewed and followed, you are now ready to use the tool. Click on the buttons below to begin learning how.

Failure to hold the tool perpendicular or allowing the tool to recoil, could allow a fastener to ricochet, make a poor quality fastening and cause excessive wear to the tool. To get the best fastening, hold the tool with both hands.

The following animation demonstrates the proper placement of the tool against your work surface.

Always make a test fastening using the lowest power level recommended for the particular tool. The chart on this page represents the Powder Load Identification by both color and number. Later in this course you will be asked to perform an exercise demonstrating that you can identify these loads by color and number.

Using a fastener as a center punch, perform the Center Punch Test by striking the fastener against the work surface using an average hammer blow. Check the results:

- If the fastener point is flattened, the material is too hard.

- If the fastener penetrates the material easily, the material is too soft.

- If the material cracks or shatters, the material is too brittle.

- If the fastener makes a small indentation into the material, the material is suitable.

IMPORTANT!

Please remove powder load from tool prior to maintenance and cleaning.

Standard powder loads contain lead. Cleaning powder actuated tools may generate lead dust. Appropriate personal protective equipment (PPE) must be worn when servicing tools.

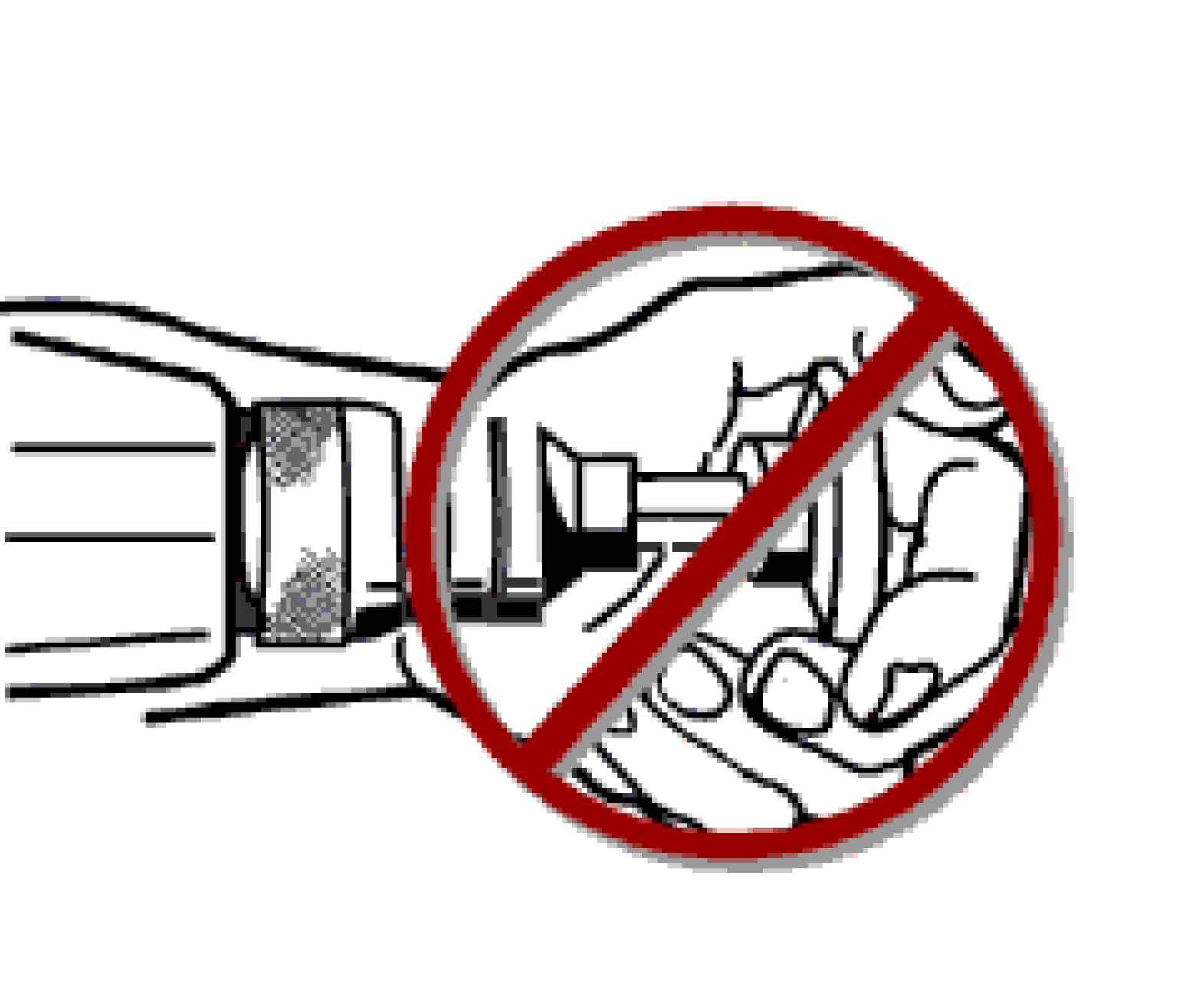

A malfunctioning tool can be dangerous to the user or bystanders and should be immediately removed from service. In the event that you encounter a malfunctioning tool, remember:

- Never disassemble a jammed, stuck or broken tool that contains a live power load. This may cause the tool to fire unintentionally.

- Always point a jammed tool away from yourself and others.

It is extremely important that you be familiar with all sections of the Operator's Manual for each tool. Valuable information, including Tool Safety, Performance, Maintenance, Troubleshooting and Fastener Selection guides, can be found in the manuals.

Operator’s Manuals in Adobe PDF formats will be available to be downloaded via each tool’s product page. The links to the products will be provided upon completion of the course.

Never attempt to fasten into very hard or brittle materials such as cast iron, tile, glass, or rock of any type. These materials can shatter, causing the fastener and/or base material fragments to fly free and cause serious injury.

Fastening into soft base materials, such as drywall or lumber products can also cause problems. These materials allow the fastener to travel completely through and out the other side, endangering those in the path of the fastener.

To achieve optimum holding power, it is recommended that fastener penetration be approximately:

- 1" for average concrete (3000 to 4500 psi) or hard concrete (4500 to 6000 psi)

- 1-1/2" in soft concrete (2000 to 3000 psi).

Minimum Shank Length = Thickness of Material (M) + Required Penetration (P)*

*approximately 1”

When fastening into concrete,always maintain a minimum spacing of at least 3" between fastening and 3" from any free edge. The primary exception can occur in a sill plate application where, by necessity, the edge distance is reduced.

When fastening into steel,always maintain a minimum spacing of at least 1½ " between fastenings and ½ " from any edge.

Note: A pre-drilled hole in the steel is considered to be an edge.

After being sure that the base material is suitable for powder actuated fastening (Center Punch Test), always make a test fastening. Begin with the lowest powder load level for that particular tool. If it does not fully set the fastener, try the next higher power level load until the proper level is found.

Load power level is determined by color or number. In this exercise, you will be tested to determine your ability to distinguish color. If you are color deficient, you MUST be able to distinguish load power level by number.

Fill in correct letter for each color.

POWER LOAD IDENTIFICATION

A

B

C

D

E

F

Individual Tool Manuals are available online for your reference.

Click the button to launch the Ramset website where each tool will be displayed. Please click on your desired tool to download the corresponding Adobe PDF Tool Safety and Operating instruction Manual.

Please visit the following pages in order to move onto the exam

Congratulations! You have completed the Ramset Powder Actuated Tool online training course and are now ready to take your licensing exam.